Slitting knife is a very Precision tool, slitter knife includes top knife and bottom knife, they are both installed on the knife axis of the slitting machine

By the principle of rolling shear,they mainly used for slitting for Capacitor paper and Aluminum foil,film cutting ,Net yarn,Sided adhesive conductive materials

category of slitting

- Cutting to length knife

Cutting to length knife holded on the turret of the cutting machine,During the forwarding of the material, the knife will fall and the knife will cut the material longitudinally ,then achieve to the purpose of cutting

Cutting to length knife include The single side blade and The double-sided blade

It is better to cut thicker and stronger rigidity film with single side blade , because the hard blade is not easy to displace at the high speed of slitting machine, and the product quality can be guaranteed. The single side blade is recommended for thickness 70-130um.

The double-sided blade is softer and suitable for slitting the thin material, so that the smoothness of the film edge can be guaranteed, and the service life can also be prolonged. If the material thickness is under 70um, it is recommended to use double-sided blade.

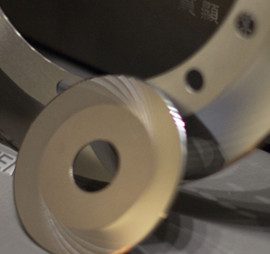

- Rotary slitting knife

Usually,we slit film,paper,Aluminum foil by rotary knife,

There are two slitting way by the rotary knife,they are top and bottom disk rotary knife slitting and squeezed slitting

There are two types of the top and bottom disk rotary knife slitting way

They are Tangent, non-tangent

- Tangent cutting way is the material be slitted along the top and bottom disc knife tangent direction, this cutting way is more convenient, In this way,the top disc knife and bottom disc knife can be easily adjust the position according to the cutting width requirements, However,obviously,the drawback is that the material at the cutting point prone to drift phenomenon, so the accuracy is not high.Non-tangent slitting is the slitted material has a certain angle with the top disc knife , the top disc knife fall down to cut the material . This cutting method can make the material not easy to drift, with high precision cutting. But the installation of knives is not very convenient, the whole shaft must be removed when installation

- squeezed slitting not commonly be applied.it is mainly constituted by The bottom roller which is synchronized with the material speed and had a certain angle with the material and the pneumatic cutter which adjusted convenientBy this slitting way,not only can slit much more thinner film,but also can slit thicker paper and non-woven fabric etc.this is the future way we can apply in slitting industry.