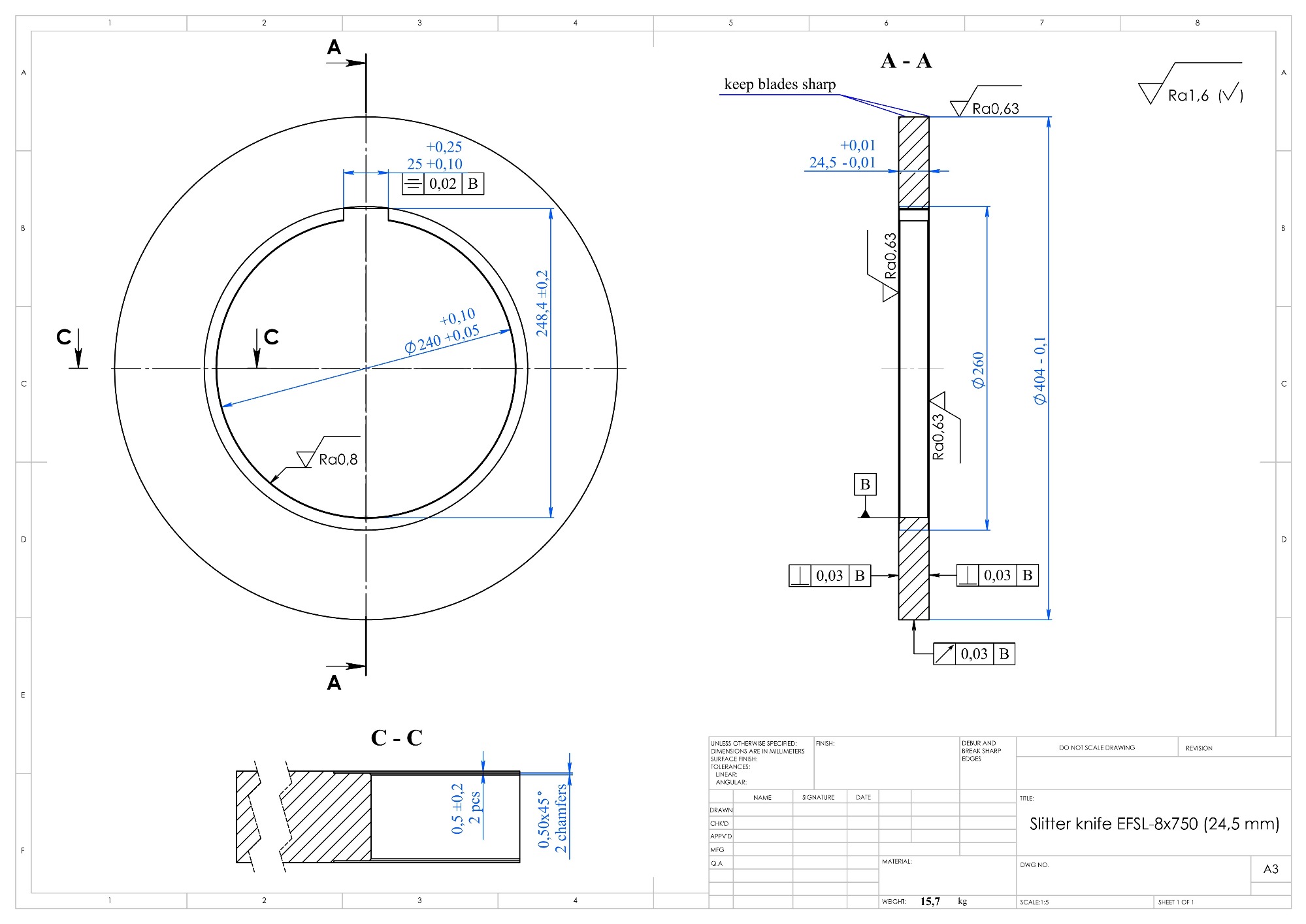

the shear angle of slitting line depend on The diameter of the slitter knife,The larger the outer diameter, the smaller the shear angle, the smaller the motor power required, and the more energy-saving. But if the diameter is too large, the rigidity of the slitter knife will be weakened and the service life of the slitter knife will be shorter. The thickness of the slitter knife determines the strength of the knife , but if the knife is too thick, it will be very heavy. It is not only hard to operate, but also expensive. meanwhile, the thickness of the slitter knife is restricted when slitting narrow strips. If the knife is too thin, the deflection of the cutter knife is not enough, and the side clearance of the cutter knife varies greatly during shearing. Cutting incisions and shapes will change, and the wear of the cutter knife will also be faster. As a vulnerable part of disc shear, the machining accuracy and hardness of disc slitter knife play a very important role in its service life. According to practical experience, the thickness accuracy of disc slitter knife is 0.005mm, the flatness accuracy is 0.025mm, and the parallelism accuracy of both sides is 0.005mm. In the processing of slitting line ,the disc slitter knife cutter edge will appear to wear and blunt angle due to the long time of anti-extrusion with the plate, and the metal fatigue layer will appear at the cutting site. To ensure the shear quality, it is necessary to grind the worn cutter disc. The disc slitter knife plays a very important role in the accuracy of coil slitting line

the axial clearance of slitter knife

The reserved size of the axial clearance of the disc slitter knife should be according to the thickness and strength of the coil strip.Generally, the ratio of tear zone to shear zone is about 2:1

We can measure the slitter side gap is suitable according to the color and roughness of shear section, the section is smooth and shiny, the side gap is too small; the section is lead-gray, the side gap is slightly small; the section is white with lead-gray, and the side gap is suitable; the section is white, granular and rough, and the side gap is too big. If the clearance is too large, shear burr will appear. If the clearance is too small, it will lead to too large load of disc slitter knife , so that cause to serious wear and tear of dice slitter knife, cause to be shorter service life. In the production process, the side clearance values of both sides of the disc slitter knife should be as consistent as possible. Because on the side with large side clearance, the cut off indentation will become larger, result in more stretching strengthened than that on the side with small side clearance, and the shear sickle bending will occur. Especially for the steel plate (narrow strip) with smaller ratio of plate thickness to plate width, the probability of sickle bending is higher.

precision of slitting tool shaft

Accuracy of slitting shaft includes horizontal swing, vertical swing and axial swing of tool axis.Usually, the accuracy of horizontal and vertical swing of cutter shaft is required to be within 0.005mm. axial swing of tool axis within 0.005mm. The accuracy of slitting tool shaft

plays an important role in achieving the stability of the side clearance the deviation of the slitter tooling

No Comment

You can post first response comment.