Definitions

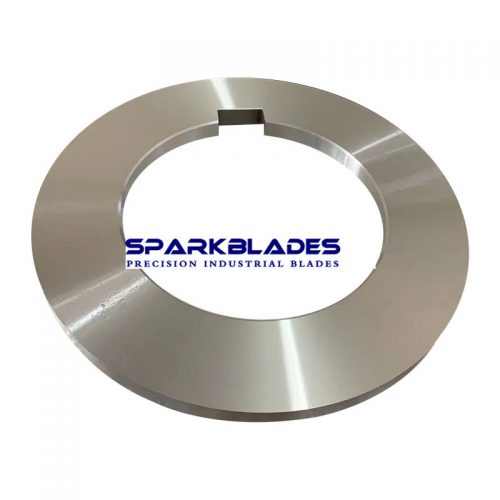

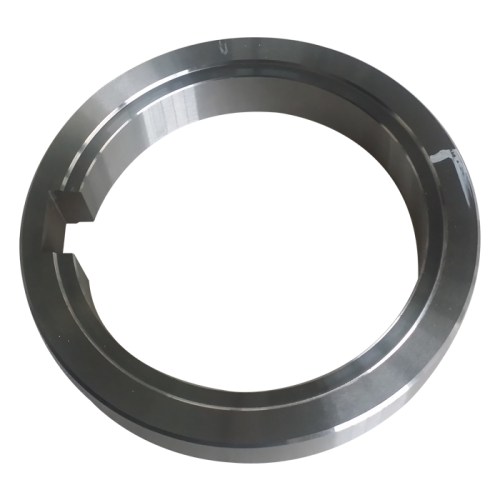

The slitting knives are mainly applied for the sheet metal plate, strip, leather,Aluminum foil,film cutting and packaging machinery. The material is made of high quality cutting tool steel 9CrSi, SKD, SKH, T10, 6CrW2Si, Cr12MoV, LD, D2,H13 and W18Cr4V. After a perfect vacuum heat treatment processing , making hardness uniform, and precision machining systemly. Making The slitting knives have the characteristic of smooth sharp cut, edge wear resistance. They can be Integrated for all kinds of slitting units.

The slitting knives are the most important part of the cutting tool, they require high processing precision during machining . For the flatness, SPARKBLADES use ultra-precision flat grinding machine, with a special grinding method, and strictly quality controlling, ensure that all finished product with thickness tolerance, parallelism tolerance achieve to 0.005mm (max) or less.

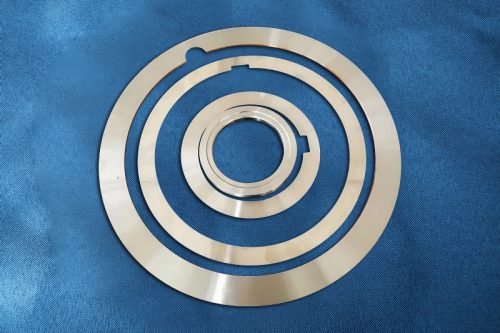

In a complete rotary slitting system , also includes Stripper Rings&Spacers and Knife holders.the mainly function is making the slitting knives keep a certain width and adjust the Horizontal clearance of top and bottom knives,the thickness usually between 0.8mm and 150mm,the hardness must be HRC45 above.Also the thickness tolerance of the spacers must be achieve to 0.005mm (max) or less.the surface of inner bore and outer cylindrical are blacken processing. effectively improve the anti-rust performance

We can supply the following components:

- Rotary Slitter Knives

- Stripper Rings&Spacers

- Knife holder

-

Galvanized Steel Coil Slitting Blades

View Detail -

High precision aluminum coil slitting knives

View Detail -

Rotary disc blade knife for coil slitting line

Read More -

Rotary shear blades for hot rolled coils

View Detail -

rotary side trimmer knives for edge trimming

View Detail -

Rotary Slitter Knives For Cutting Stainless Steel Coils

View Detail -

rubber bonded spacer for slitting line

View Detail -

Rubber Bonded Stripper Rings

View Detail -

Slitting blades used for hot steel plate

View Detail -

steel spacers of coil slitting line tools

View Detail -

steel stripper rings of slitting line tools

View Detail -

Ultra-Precision Quills

View Detail