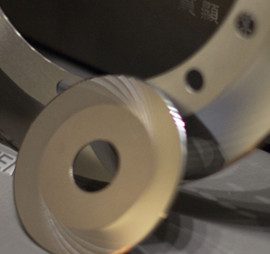

As the name implies,why slitting blade is called the cutting blade,as the the slitting blades are uesd for slitting material,such as slitting steel plate,also slitting paper and textile etc.they are applied very widely in market.so today we will discuss how to choose slitting blades for slitting your material.

Sometimes we need to cut the fruit,Fruit has water,so if your sliiting blades made from ordinary steel material,they are rusts easily,

Sometimes we need to cut Corrosive material,and our slitting blades must be Corrosion resistant.

Sometimes we need to cut very hard strip steel.Then the blade will break immediately.

Now we must consider the material of the blades

9CRSI, this material has higher hardenability and hardenability,they usually used to make a huge shape,

cr12mov,also is widely used in producing slitting blades,But the disadvantage of this kind of steel is it’s poor toughness,But as the result of it’s good wear resistance,many slitting blades factories choose this material,they use this material to make Cold work die steel,they are widely applied in paper slitting blades and packaging cutting blades.

Different cutting blades made from Different steel material,also they cutting different material.so when we need cutting some material,We can only choose the most cost-effective.