Abstract: This article describes authors design of high - precision edge trimmer and his commissioning experience,analyzes factors affecting trimming quality and puts forward the measure for improving trimming quality.

With the increasing popularity of aluminum belt products in the national economy,and the quality of the strip material is required by people more and more high , while the edge of the strip Quality (ie, no cracks, tearing, mezzanine, burrs, highlights) is one of most important indicator of quality of the strip material

In the production line of aluminum alloy strip, rotary slitter knives of Edge Trimmer are very important equipment set.that will require good Structural design of rotary slitter knives

The design of rotary slitter knives of Edge Trimmer has much important relationship with the thickness of the strip material,the more thick, the easier of guarantee of the quality ,the more thin,the more higher require for designing

The practice shows that the thickness of the strip material between 0.4mm and 1mm, the trimming quality is much more easier to guarantee,the thickness of the strip material above 1mm,the edge trimmer is the Intermediate process,that’s not require more for the trimming quality, when trimming for the thickness between 0.1mm and 0.4mm of the finished strip material,the requirement for the installing and adjusting the top and bottom of the rotary slitter knives is very high.

Design for the knife holder

OMITS

Guarantee measures for high precision trimming

When trimming the thinner strip material (0.4mm lower),To ensure a good trimming quality, not only required for a rational design of the knife holder.but also have high degree requirement in slitter system assembling

- Select rational gap value

Rational gap value is an Important premise for reaching high trimming quality.Different thickness of strip material corresponding to different gap value.according to the rotary slitter knives designing experience and referring to practical experience in production.we design seven spacers specification(figure 1),all of the spacers’ hardness are HRC45-50.

figure 1 spacers specification

| thickness of strip material(mm) | thickness of spacers(mm) | gap of spacers(mm) | numbers |

| 0.1-0.25 | 10-0.012 | 0.012 | 2 |

| 0.25-0.4 | 10-0.033 | 0.033 | 2 |

| 0.4-0.6 | 10-0.048 | 0.048 | 2 |

| 0.6-1.0 | 10-0.071 | 0.071 | 2 |

| 1.0-1.3 | 10-0.107 | 0.107 | 2 |

| 1.3-2.0 | 10-0.160 | 0.160 | 2 |

| 2.0-2.5 | 10-0.240 | 0.240 | 2 |

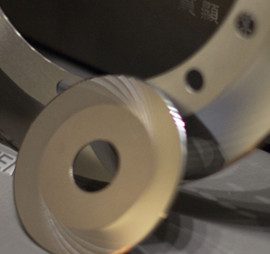

- Rational strip rings size

The strip rings are application for stabilizing the material and protecting the material surface Therefore we must choose different thickness and diameter corresponding to different thickness of strip material.Strip rings include Steel Stripper Rings and Rubber Bonded Stripper Rings.The inner ring is steel rings,and out of it is Rubber Bonded Rings.we design the following specification(figure 2)

figure 2 Rubber Bonded Stripper Rings specification

| knife hold | thickness of strip material | thickness of rubber rings | diameter of rubber rings | numbers |

| top knife | 0.1-1.5 | 90 | 250+0.5 | 2 |

| 1.5-2.5 | 90 | 250+0 | 2 | |

| bottom knife | 0.1-1.4 | 75 | 250+0.5 | 2 |

| 0.4-1.0 | 75 | 250-0.5 | 2 | |

| 1.0-1.8 | 75 | 250-1.0 | 2 | |

| 1.8-2.5 | 75 | 250-2.3 | 2 |

- Strictly assembly knife hold.

It should be rigorously assembled as follows:Reference shoulder face pulse should be controlled under 0.003mm,the shaft diameter pulse should be controlled under 0.025mm,top and bottom knife axis parallelism should be under 0.025mm.