Eastern of Han Iron and Steel Cold Press Factory uses Austria ANDRITZ company’s push-pull pickling line. Rotary slitter knife is one of the very important equipment of the production line, in which the operation of the cutting edge of the rotary slitter knife and scrap cutter directly affect the quality of edge trimming material and work efficiency. In the production of edge trimming material, once the edge breaking of the cutting edge of the rotary slitter knife and scrap cutter appeared, especially the rotary slitter knife can not automatically prepared after being replaced, usually be treated as waste or rewashing roll. This not only increasing the usage amount of the cutting edge and the increase in labor ,but mainly led to an increase in parking time, which seriously affected the problem of lower production quality and cost. So effectively reducing the cutting edge breaking accident, reducing the using of cutting edge, improving the service life of the rotary slitter knife and the scrap cutter is the fundamental to reduce production costs, improve production efficiency .

Ⅱ. Analysis of several causes of

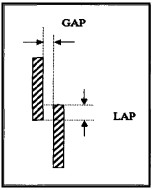

- Adjustment correction error of the rotary slitter knife’s LAP and GAP (figure 1) is one of the most important reasons for the breakage of the cutting edge.

figure 1

| Cutting Thickness | GAP | LAP | Cutting Thickness | GAP | LAP |

| 0.8 | 0.08 | +0.40 | 3.2 | 0.36 | +0.12 |

| 0.9 | 0.09 | +0.45 | 3.4 | 0.38 | 0.08 |

| 1.0 | 0.10 | +0.50 | 3.6 | 0.40 | 0.04 |

| 1.2 | 0.12 | +0.59 | 3.8 | 0.42 | 0.00 |

| 1.4 | 0.14 | +0.65 | 4.0 | 0.45 | -0.04 |

| 1.6 | 0.17 | +0.60 | 4.2 | 0.47 | -0.08 |

| 1.8 | 0.20 | +0.50 | 4.4 | 0.49 | -0.11 |

| 2.0 | 0.22 | +0.40 | 4.6 | 0.51 | -0.13 |

| 2.2 | 0.25 | +0.35 | 4.8 | 0.54 | -0.18 |

| 2.4 | 0.27 | +0.30 | 5.0 | 0.56 | -0.23 |

| 2.6 | 0.29 | +0.27 | 5.5 | 0.61 | -0.28 |

| 2.8 | 0.31 | +0.23 | 6.0 | 0.67 | -0.35 |

| 3.0 | 0.34 | +0.18 |

Schedule 1:the relationship of cutting thickness with GAP and LAP(reference value)

In the process of rotary slitter knife shearing, the calibration of GAP and LAP are quite important . Only in GAP and LAP were correctly calibrated in advance, rotary slitter knife can automatically adjust the standard GAP and LAP according to the thickness of the steel strip (Table 1 ) . If the correction is inaccurate, resulting in GAP automatically adjusted by thickness during shearing and the actual LAP in the thickness is in error. At this point, the edge trimming of rotary slitter knife is not only poor quality, but working under abnormal parameters, the cutting edge can easily crack.thus the calibration of GAP and LAP is critical to prevent the cutting edge breaking.

- The deformation or damage of the rubber bonded spacer of the rotary slitter knife is also one of the important reasons for cutting edge breaking.

The cutting edge of top rotary slitter knife is equipped with two rubber bonded spacer and the lower cutting edge is fitted with one rubber bonded spacer, these three rubber bonded spacer have a significant effect on the protection of the cutting edge. In the high-speed operation of the strip, the rubber bonded ring B and the next rubber bonded ring C will be tightly added in the middle of the strip steel, with a stable effect. The above rubber bonded ring A will be pressed on the lower edge of the strip steel to prevent strip vibration, the main role is to reduce the impact of the strip steel on the cutting edge. Once any rubber bonded ring deformation, damage, cracking, slipping, wearing does not run in parallel with the cutting edge, will lead the strip steel impacting the cutting edge to reduce the using time. when the high-speed operation,If the rubber bonded ring was deformated it can not only take a shockproof, stable effect, but will cause the vibration of the strip, resulting in cutting blade life shortened.

- The unstandardized installation of the cutting edge of the rotary slitter knife and scrap cutter is also one of the reasons caused cutting edge breaking.

Whenever installing the rotary slitter knife and scrap chopper knives, we must pay attention to the cleanness of cutting edge and knife hold, can not be stained with oil, dust, iron, cloth and other items. The working face of cutting edge can not have any damage, should be lightly put. After the installation of the cutting edge, the top of the locking nut must be symmetrical tightened, and the scrap chopper knives cutting edge should be ensured that the thickness of 25mm. If necessary, it can be added to the gasket or copper to adjustment. All above are not properly installed can make the cutting edges work under abnormal conditions and are prone to damage.

- Both sides of the the rotary slitter knife’s edge trimming width is uneven, that is, the trimming width of on side is smaller and the other side is larger will lead to clipping or damage of the cutting edge.

If the offcut material of strip steel cutting by rotary slitter knife are one side wide and the other side narrow, according to the situation ,if occasionally one roll appeared,it is indicating that the flatness of strip steel itself is poor, with the condition of camber. In this condition maybe it is caused by strip steel deviation . If it happen much more common, it indicates that the centerline of the rotary disc slitter knife is offset from the centerline of the production line, or that the 5 # CPC centerline does not coincide with the centerline of the rotary disc slitter knife. Because the edge of the wire is not hard enough,the narrow side sometimes not easy to follow the guide groove into the scrap cutter to break up, often appear directly in the guide groove or the edge of the shear seam.Because of high-speed operation of the strip steel, once the accumulation of expansion, and immediately cause friction with the cutting edge , resulting in cutting edge quickly break or directly damage.

- the poor flatness of strip steel will also cause cutting edge breaking

The raw plate is poor, especially the serious wave plate after cutting edge due to fluctuations in the cutting edge can impact the cutting edge , easily make the cutting breaking